Letting Go of Our Love Affair with Exposed Structure

Why some Pacific Northwest design aesthetic choices need consideration in light of climate change and carbon reduction

North Cascades Environmental Learning Center, designed in 2009 at the start of LEED certification and green building practices, with exposed heavy timber structure

Many different architectural styles lean on exposing structural elements from interior to exterior for character and function. We see examples of wood, steel, concrete and other materials used to cantilever the roof and floor assemblies outward to provide decks, overhangs, or mere decoration. Yet each time these elements flow from the conditioned interior space to the exposed elements outside, they provide a means for heat loss or gain for the building.

Most of us are guilty of it. Whether it’s roof rafters exposed at the eave edge or heavy timber beams jutting out to provide much needed cover from Pacific Northwest rains, it has become a fairly common approach to architecture. Most of us haven’t thought too much about the impact that it might have on our building’s resiliency or carbon footprint. But we should.

It’s just wood; how bad could it be?

Wood is often thought of as a great environmental material for structure. And as mass timber projects gain in popularity, there is a growing trend in exposing these heavy and mass timber elements from inside to out. While wood is certainly a better insulator than steel, it’s not much better than concrete. If you’ve felt a concrete wall exposed to weather, you know to sit next to it in the summer to enjoy the warmth and to stay away from it in the winter to avoid the chill. This tells you how much heat transfer there is coming through every beam or rafter in our designs.

These THERMAL BRIDGES are problematic for a couple reasons. First, and most obvious, they allow for heat loss or gain through the envelope. This means for every penetration or thermal bridge that we as designers add to our projects, we are asking the mechanical system to compensate with additional heating or cooling. Unless you are a net-zero energy project, that means adding some form of electricity or fossil fuel to compensate for that design feature. Secondly, they introduce potential pathways for moisture to enter the building assemblies, causing condensation that can result in mold and/or deterioration of the building products. Third, every penetration in the envelope provides potential for air leakage if not properly sealed. Air leakage leads to heat loss and gain as well as potential indoor air quality issues.

So What’s the Answer?

The best thing we can do is eliminate structural penetrations through the exterior envelope if they are not fully insulated. If that look is still desired or there is a need for exterior porches, decks, and overhangs, it may be possible to use isolated supporting structure on the outside of the buildings, or use thermally broken ledgers, beams and columns to eliminate the thermal bridge between outside and in. It’s a little more work in design, but it has significant impact on energy savings, long-term durability, and indoor air quality.

Lake Cavanaugh Residence with no gable eave and exterior brackets supporting the overhanging eaves. This project was designed in the 1990s before many of these concerns were considered. While doing well for the walls and roof, there is more than can be done on projects like this to insulate and thermally break the floor and supporting wood structure below.

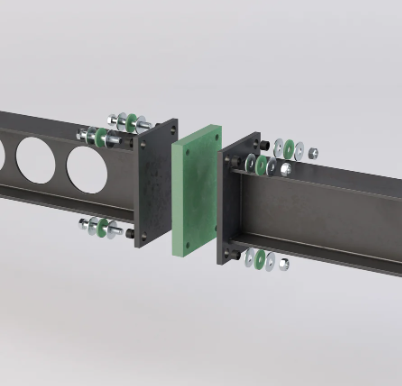

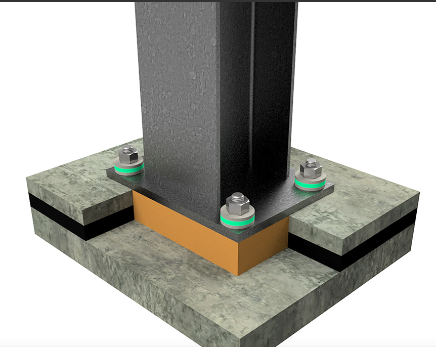

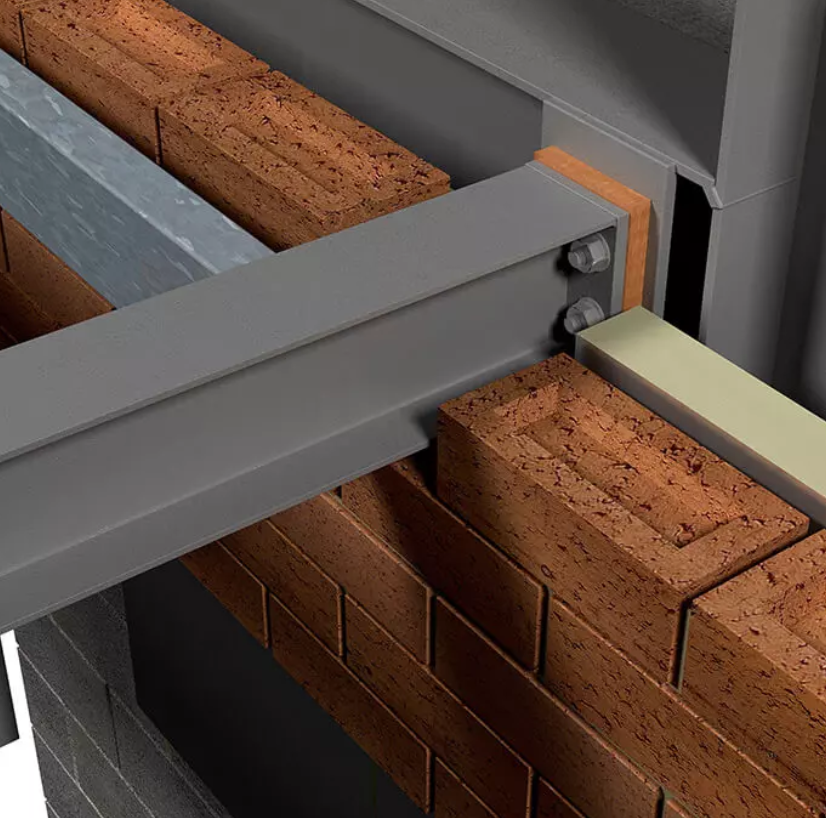

We can also use thermal break materials, insulation, and air sealing where we absolutely need to have these penetrations. Many manufacturers provide low, medium, and high-density thermal break materials that can be used in most situations with the collaboration of our structural engineers.

Thermal break materials by Fabreeka (image 1 and 2) and Aratherm (image 3)

Passive House design takes into consideration every single thermal bridge in the design. If these bridges are not mitigated, they get calculated into the WUFI Energy Model to see if it can still pass certification. This includes every brick tie, anchor, and fastener. By eliminating these bridges, we can make for better, more resilient buildings that use less energy, are more comfortable to occupy, and are still beautiful.

Passive House conceptual design for animal clinic using thermally separated entrance canopies and southern overhang

As we strive to make our buildings better and better in the face of changing climates and resource conservation, eliminating THERMAL BRIDGES is one way to make a significant improvement in building performance.